The Ingersoll-Rand T30 air compressor manual provides a comprehensive guide for installation, operation, and maintenance, ensuring optimal performance and safety. This model is known for its reliability and efficiency in industrial applications, making it a trusted choice for professionals. The manual is essential for understanding the compressor’s features, troubleshooting, and adhering to safety protocols. By following the guidelines, users can maximize productivity while minimizing risks. This document serves as a vital resource for anyone working with the T30 model.

1.1 Overview of the Ingersoll-Rand T30 Air Compressor

The Ingersoll-Rand T30 is a robust industrial air compressor designed for heavy-duty applications. It ensures high performance and reliability, making it ideal for demanding environments. The compressor is electric-driven, available in single or two-stage configurations, and features non-lubricated, air-cooled cylinders for instrument-quality air. With a focus on durability and efficiency, the T30 is widely used in industries requiring consistent airflow. The manual provides essential details for proper installation, operation, and maintenance, ensuring optimal functionality and safety. Users can rely on this guide to understand the compressor’s components and operational requirements fully.

1.2 Importance of the Manual for Users

The manual is crucial for safe and efficient operation of the Ingersoll-Rand T30 air compressor. It provides detailed instructions for installation, maintenance, and troubleshooting, ensuring users can address issues promptly. The guide includes safety precautions to prevent accidents and maintain equipment longevity. By following the manual, users can optimize compressor performance, reduce downtime, and comply with manufacturer recommendations. This comprehensive resource is essential for both novice and experienced operators, offering clear guidance to maximize productivity while minimizing risks. Regular reference to the manual ensures the compressor operates at its best, supporting industrial applications effectively.

1.3 Key Features of the T30 Model

The Ingersoll-Rand T30 air compressor is an electric-driven, single and two-stage model designed for high reliability and efficiency. It features non-lubricated, air-cooled cylinders, ensuring instrument-quality air output. The compressor is known for its durability and minimal maintenance requirements, making it ideal for industrial applications. Its compact design and robust construction allow for consistent performance in demanding environments. The T30 model also offers adjustable pressure settings and advanced monitoring capabilities, enabling precise control over airflow and pressure. These features make the T30 a versatile and reliable choice for users requiring high-performance air compression solutions.

Safety Guidelines

Adhere to safety instructions for installation, operation, and maintenance to prevent accidents and ensure safe operation of the Ingersoll-Rand T30 air compressor.

2.1 General Safety Precautions

Always follow safety guidelines to prevent accidents and ensure safe operation of the Ingersoll-Rand T30 air compressor. Wear protective gear, including safety glasses and gloves, when operating or maintaining the compressor. Ensure proper ventilation in the workspace to avoid inhalation of compressed air or gases. Never overload the compressor beyond its rated capacity, as this can lead to mechanical failure. Keep the area around the compressor clean and free from obstructions to prevent tripping hazards. Regularly inspect hoses and connections for damage or leaks. Adhere to all safety instructions provided in the manual to minimize risks and ensure reliable performance. Proper safety practices are essential for protecting both the operator and the equipment.

2.2 Handling and Storage Safety Tips

Always use proper lifting techniques or equipment, such as forklifts or dollies, to move the Ingersoll-Rand T30 air compressor to avoid injury or damage. Ensure the compressor is securely fastened during transport to prevent shifting. Store the unit in a dry, cool, well-ventilated area away from flammable materials. Keep the compressor upright to prevent oil or coolant leakage. Avoid exposure to extreme temperatures or humidity, as this can affect performance and longevity. Disconnect power sources and drain moisture from tanks before storage. Use protective covers to shield components from dust and environmental factors. Follow manufacturer guidelines for proper handling and storage to maintain safety and functionality.

2.3 Emergency Procedures

In case of an emergency, immediately shut off the power supply to the Ingersoll-Rand T30 air compressor and evacuate the area if necessary. For system malfunctions, stop operation and contact authorized personnel or Ingersoll-Rand support. In case of a sudden pressure release or gas leak, isolate the area and ventilate thoroughly; If the compressor overheats, turn it off and allow it to cool before inspecting for damage. For electrical issues or short circuits, disconnect power and avoid water usage. In case of natural disasters, secure the compressor to prevent damage. Always follow emergency shutdown procedures outlined in the manual to ensure safety and minimize risks.

Installation Requirements

Ensure a stable foundation, proper ventilation, and suitable electrical connections. Install according to manufacturer guidelines, using correct tools and materials for optimal performance and safety.

3.1 Necessary Tools and Materials

For proper installation of the Ingersoll-Rand T30 air compressor, ensure you have the following tools and materials: wrenches, screwdrivers, pliers, and a level. Required materials include a suitable power supply cable, compressed air hoses, and connectors. Additional items like a drain kit, pressure gauge, and mounting brackets may be necessary. Ensure all components are compatible with the compressor’s specifications to avoid damage or malfunction. Refer to the manufacturer’s guidelines for specific recommendations on tools and materials to guarantee a safe and efficient setup. Proper preparation is key to achieving optimal performance and longevity of the equipment.

3.2 Site Preparation and Layout

Proper site preparation is crucial for the efficient operation of the Ingersoll-Rand T30 air compressor. Begin by selecting a well-ventilated area to prevent overheating and reduce noise levels. Ensure the floor is level and sturdy to maintain compressor stability and minimize vibrations. Position the unit away from direct sunlight and moisture to prevent damage. Allow sufficient space around the compressor for easy maintenance access. Ensure proximity to a power supply and air distribution lines to minimize connection lengths. Proper drainage should be planned for condensate removal. A clean, dry, and well-organized layout ensures optimal performance and longevity of the equipment.

3.3 Step-by-Step Installation Process

Carefully unpack the compressor and inspect for any damage or wear from shipping.

Position the unit on a level, stable surface to ensure balanced operation.

Secure the compressor firmly to prevent any movement during operation.

Connect the power supply, ensuring it matches the specified voltage and current requirements.

Attach the air intake and discharge lines to the correct ports, using appropriate fittings.

Perform a low-pressure test to identify any leaks or issues.

Gradually increase the operating pressure while closely monitoring the unit’s performance and vibrations.

Check all connections for tightness and ensure there are no leaks.

Conduct a full-load test to verify optimal functioning and performance.

Document the installation process, settings, and any adjustments made for future reference and maintenance.

Operating Instructions

Start the compressor, gradually increase pressure, monitor output, and adjust settings as needed. Regularly check performance and ensure smooth operation for optimal results.

4.1 Starting and Stopping the Compressor

To start the Ingersoll-Rand T30 air compressor, ensure it is placed on a flat, stable surface and plugged into a suitable power source. Turn the power switch to the “on” position and allow the unit to reach the desired pressure. When stopping, reduce the workload gradually and press the “off” switch. Always follow safety guidelines and manufacturer instructions for proper operation and shutdown to maintain safety and efficiency.

4.2 Adjusting Pressure Settings

Adjusting the pressure settings on the Ingersoll-Rand T30 air compressor involves using the regulator and pressure gauge. Locate the regulator knob and turn it clockwise to increase pressure or counterclockwise to decrease it. Monitor the gauge to ensure the pressure matches your requirements. Always operate within the compressor’s recommended pressure range to avoid damage. After adjusting, test the system at a low setting to confirm proper function. Regularly check and adjust the pressure to maintain optimal performance and safety during operation.

4.3 Monitoring Performance and Output

Monitoring the performance and output of the Ingersoll-Rand T30 air compressor is essential for ensuring optimal operation. Regularly check the pressure gauge to verify that the output pressure aligns with your requirements. Monitor the airflow to ensure it meets the demand of connected tools or equipment. Use the built-in sensors to track temperature and pressure levels, which help prevent overheating or overloading. Inspect for air leaks in hoses and connections, as these can reduce efficiency. Additionally, observe the motor’s current draw and operating temperature to ensure they remain within specified limits. This regular monitoring helps maintain productivity and extends the compressor’s lifespan.

4.4 Daily Operational Checks

Performing daily operational checks on the Ingersoll-Rand T30 air compressor ensures smooth and efficient operation. Begin by inspecting the compressor unit for any visible damage or wear. Check the air filter for cleanliness and replace it if necessary. Verify the oil level and top it off as needed to maintain proper lubrication. Inspect the belt for tension and signs of wear, adjusting or replacing it as required. Ensure all connections, including hoses and valves, are secure and free from leaks. Finally, drain any accumulated condensate from the tank to prevent moisture buildup. Regular checks help maintain performance and prevent potential issues.

Maintenance and Repair

Regular maintenance ensures optimal performance and longevity of the Ingersoll-Rand T30; Schedule routine inspections, lubrication, and filter checks. Address issues promptly to minimize downtime and extend equipment life. Use genuine parts for reliability and follow manual guidelines for safe, efficient operation.

5.1 Scheduled Maintenance Tasks

Regular maintenance is essential for the Ingersoll-Rand T30 air compressor. Daily checks include inspecting oil levels, air filters, and belts. Weekly, clean the compressor and check for leaks. Monthly, replace the air filter and inspect the drain valve. Every 500 hours, change the oil and lubricate moving parts. Annually, replace the belt and inspect the motor. Adhere to the manufacturer’s schedule to ensure optimal performance and prevent wear. Always consult the manual for specific guidelines and use genuine parts for replacements to maintain warranty and efficiency.

5.2 Lubrication and Oil Change Procedures

Proper lubrication is vital for the Ingersoll-Rand T30 air compressor. Use the specified synthetic oil to ensure optimal performance. Turn off the compressor and let it cool before starting. Drain the old oil into a pan, then replace the oil filter with a genuine Ingersoll-Rand filter. Refill with the recommended oil level. Regular oil changes prevent overheating and extend equipment life. Always refer to the manual for the correct oil type and capacity. Dispose of used oil and filters responsibly. Lubricate moving parts as specified to maintain efficiency and reduce wear. Follow these steps to ensure smooth operation and longevity.

5;3 Air Filter Cleaning and Replacement

Regular air filter maintenance is crucial for the Ingersoll-Rand T30 air compressor. Turn off the compressor and allow it to cool. Locate the air filter housing, typically near the intake valve. Remove the filter and inspect for dirt or damage. Clean reusable filters with compressed air, or replace them if damaged. Use only genuine Ingersoll-Rand replacement filters to ensure compatibility and performance. Reassemble the housing securely. Replace the air filter every 2,000 operating hours or as specified in the manual. Proper filtration prevents dust and debris from entering the compressor, ensuring efficient operation and reducing wear on internal components. Always follow safety guidelines when handling filters.

5.4 Belt Replacement and Tensioning

To ensure optimal performance of the Ingersoll-Rand T30 air compressor, regular belt inspection and maintenance are essential. Start by gathering the necessary tools and materials, including a replacement belt compatible with the T30 model. Turn off and unplug the compressor, allowing it to cool down for safety. Locate the tensioner pulley and loosen it to remove the old belt. Inspect the pulleys for wear and install the new belt, ensuring it is properly seated. Tighten the belt according to the manufacturer’s specifications, using a tool to measure tension accurately. After installation, run the compressor to check for smooth operation and adjust the tension if needed. Proper belt tension prevents slippage and extends the compressor’s lifespan. Regular belt replacements, as per the manual’s maintenance schedule, are crucial for avoiding unexpected breakdowns. Dispose of the old belt responsibly to maintain environmental standards. By following these steps, you can ensure the compressor operates efficiently and reliably.

5.5 Troubleshooting Common Issues

The Ingersoll-Rand T30 air compressor may occasionally encounter issues that require quick resolution. Common problems include low pressure output, excessive noise, or the compressor not starting. For low pressure, check the air filter for blockages and ensure proper belt tension. If the compressor is noisy, inspect the belt for misalignment or wear. Failure to start may indicate a power supply issue or a faulty pressure switch. Always refer to the manual for detailed diagnostic steps. Regular maintenance and addressing issues promptly can prevent downtime and extend the compressor’s lifespan. If problems persist, contact authorized support for assistance.

Technical Specifications

The Ingersoll-Rand T30 features a 25 HP motor, delivering up to 100 CFM at 90 PSI. It operates on 208/230/460V power and weighs approximately 500 lbs.

6.1 Compressor Ratings and Capacities

The Ingersoll-Rand T30 air compressor is rated for 25 HP and delivers up to 100 CFM at 90 PSI. It operates efficiently within a voltage range of 208/230/460V. The compressor is designed to handle maximum pressures of 125 PSI, ensuring robust performance for industrial applications. With a tank capacity of 80 gallons, it provides consistent airflow for demanding tasks. Its compact design and high-capacity output make it suitable for heavy-duty use, while maintaining energy efficiency and reliability.

- 25 HP motor for high performance.

- 100 CFM at 90 PSI for consistent airflow.

- Maximum operating pressure of 125 PSI.

These ratings ensure the T30 meets the needs of various industrial and commercial applications.

6.2 Motor Specifications

The Ingersoll-Rand T30 air compressor is equipped with a high-efficiency, 25 HP electric motor. Designed for industrial use, it operates at 208/230/460V and 60 Hz. The motor features a three-phase induction design, delivering reliable performance. With a full-load RPM of 1760, it ensures smooth operation. The motor also has a power factor of 0.8 and meets NEMA premium efficiency standards, reducing energy consumption. Its continuous-duty rating and robust construction make it suitable for demanding environments. Proper installation and wiring are essential to ensure optimal performance and safety.

- 25 HP, three-phase induction motor.

- 208/230/460V, 60 Hz operation.

- 1760 RPM full-load speed.

- NEMA premium efficiency rating.

This motor ensures reliable and efficient operation for the T30 compressor.

6.3 Dimensions and Weight

The Ingersoll-Rand T30 air compressor has a compact design with dimensions of 49 inches in length, 28 inches in width, and 47 inches in height. It weighs approximately 595 pounds, making it manageable for installation in various industrial settings. The unit is designed to be space-efficient while maintaining durability and performance. Proper handling equipment is recommended for moving the compressor due to its weight. Ensure the installation site can accommodate its dimensions to allow for proper airflow and maintenance access.

- Dimensions: 49″ L x 28″ W x 47″ H.

- Weight: Approximately 595 pounds.

- Compact design for space efficiency.

These specifications ensure ease of placement and operation in industrial environments.

6.4 Noise Levels and Vibration

The Ingersoll-Rand T30 air compressor operates at a noise level of approximately 80-90 decibels during normal operation. This is typical for industrial air compressors and may require hearing protection in prolonged exposure scenarios. Vibration is minimized through the use of rubber mounts and a balanced design. Proper installation on a sturdy, level surface further reduces vibration. Regular maintenance, such as ensuring all bolts are tightened and components are aligned, helps maintain low vibration levels. Operating in a well-ventilated area can also mitigate noise concerns.

- Noise level: 80-90 decibels.

- Vibration reduction features.

- Importance of proper installation.

These factors ensure smooth operation and reduced disturbance in industrial environments.

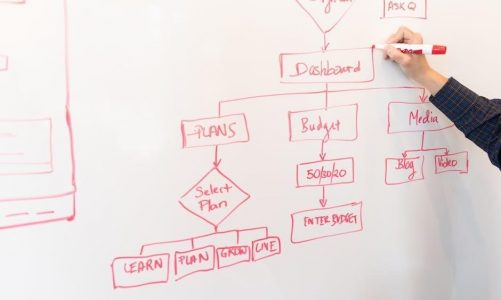

Parts Diagram and Components

The parts diagram provides a detailed visual representation of the T30 compressor, identifying key components like the motor, pump, and control panel. It aids in maintenance and repairs by ensuring compatibility of replacement parts.

- Visual guide for component identification.

- Essential for maintenance and repairs.

- Ensures correct part compatibility.

7.1 Understanding the Parts Diagram

The parts diagram is a visual guide that illustrates the T30 air compressor’s components and their relationships. It helps users identify and locate parts efficiently, ensuring proper maintenance and repairs. The diagram typically includes labels, reference numbers, and detailed illustrations of major components like the compressor pump, motor, and control panel. Understanding this diagram is essential for troubleshooting and replacing parts correctly. Always refer to the diagram when performing maintenance or repairs to ensure accuracy and safety. It serves as a critical resource for both novice and experienced users, promoting effective compressor operation and longevity.

- Visual representation of compressor components.

- Essential for accurate maintenance and repairs;

- Enhances troubleshooting and part replacement.

7.2 Key Components and Their Functions

The Ingersoll-Rand T30 air compressor features several critical components designed for optimal performance and reliability. The compressor pump is the core, responsible for compressing air. The electric motor powers the pump, while the air filter ensures clean air intake. The pressure gauge monitors output pressure, and the control panel manages operations. The cooling system prevents overheating, and the belt drives the compressor mechanism. Each component is essential for efficient air compression and delivery. Understanding their functions aids in maintenance and troubleshooting, ensuring the compressor operates at peak efficiency and extends its service life.

- Compressor pump: Core of air compression.

- Electric motor: Powers the pump.

- Air filter: Ensures clean air intake.

7.3 Compatibility of Replacement Parts

Ensuring compatibility of replacement parts is crucial for maintaining the performance and longevity of the Ingersoll-Rand T30 air compressor. Always use genuine or authorized parts specifically designed for the T30 model, as non-compatible components can lead to reduced efficiency, damage, or safety hazards. Refer to the parts diagram or consult the manufacturer for verified compatibility. Using unauthorized parts may void the warranty and compromise operational safety. Properly sourced replacement parts guarantee optimal functionality and adherence to safety standards, ensuring the compressor operates as intended.

- Genuine parts ensure optimal performance.

- Non-compatible parts can cause damage or safety risks.

- Consult the parts diagram or manufacturer for verification.

Warranty and Support

The Ingersoll-Rand T30 air compressor is backed by a comprehensive warranty program, ensuring protection for parts and labor. Dedicated customer support provides assistance with inquiries, repairs, and maintenance.

- Warranty coverage for parts and labor.

- Expert support for troubleshooting.

- Assistance with maintenance and repairs.

8.1 Warranty Terms and Conditions

The Ingersoll-Rand T30 air compressor is covered by a limited warranty that protects against defects in materials and workmanship. The warranty period typically lasts for one year from the date of purchase or 1,500 hours of operation, whichever comes first. Coverage includes parts and labor for eligible repairs. To maintain warranty validity, users must adhere to scheduled maintenance and operate the compressor as per the manual’s guidelines. Unauthorized modifications or misuse may void the warranty. For detailed terms, refer to the official documentation or contact Ingersoll-Rand customer support.

- Coverage for parts and labor during the warranty period.

- Warranty void if proper maintenance is not performed.

- Unauthorized modifications invalidate the warranty.

- Warranty is non-transferable and applies only to the original purchaser.

8.2 Registering Your Product

Registering your Ingersoll-Rand T30 air compressor is essential for warranty validation and access to exclusive support services. To register, visit the official Ingersoll-Rand website and complete the online registration form. Provide details such as the product serial number, purchase date, and your contact information. Registration ensures you receive updates, maintenance reminders, and priority customer support. Keep your proof of purchase and registration confirmation for future reference. This process is straightforward and helps maintain your compressor’s optimal performance and warranty coverage.

- Visit the official Ingersoll-Rand website for registration.

- Provide serial number, purchase date, and contact information.

- Registration offers exclusive support and updates.

- Retain registration confirmation for warranty purposes.

8.3 Contacting Customer Support

To contact Ingersoll-Rand customer support for your T30 air compressor, visit their official website or call the dedicated support hotline. Live chat and email options are also available for convenience. Be prepared to provide your product serial number and a detailed description of your inquiry or issue. Representatives are trained to assist with troubleshooting, parts ordering, and technical questions. Support is available 24/7 for urgent matters, ensuring prompt resolution and minimal downtime. Use the contact information listed in your manual or on the manufacturer’s website for assistance.

- Call the hotline for immediate assistance.

- Use live chat or email for less urgent inquiries.

- Have your serial number and details ready.

- Support is available 24/7 for critical issues.

Environmental Considerations

Promoting energy efficiency, proper waste disposal, and minimizing ecological impact are essential for responsible ownership of the Ingersoll-Rand T30 air compressor, aligning with environmental stewardship goals.

9.1 Energy Efficiency and Consumption

The Ingersoll-Rand T30 air compressor is designed to optimize energy efficiency, reducing operational costs and environmental impact. It features a high-efficiency motor and advanced compression technology to minimize energy consumption. Proper sizing and usage of the compressor, as outlined in the manual, ensure optimal performance while conserving energy. Regular maintenance, such as checking for air leaks and maintaining proper pressure settings, further enhances efficiency. By adhering to these guidelines, users can significantly reduce energy waste and lower their carbon footprint, promoting sustainable operations.

9.2 Proper Disposal of Waste Materials

Proper disposal of waste materials from the Ingersoll-Rand T30 air compressor is crucial for environmental protection. Dispose of used oils, filters, and other hazardous materials according to local and national regulations. Recycle metals and plastics whenever possible. Contaminated materials, such as oil-soaked rags, should be handled by licensed waste management facilities. Always consult local authorities for specific guidelines to ensure compliance with environmental laws. Proper disposal helps minimize ecological impact and promotes sustainable practices. Adhere to the manual’s recommendations for responsible waste management.

9.3 Reducing Environmental Impact

To reduce the environmental impact of the Ingersoll-Rand T30 air compressor, prioritize energy efficiency and responsible usage. Regular maintenance, such as cleaning air filters and checking for leaks, ensures optimal performance and minimizes energy waste. Use eco-friendly lubricants and adhere to scheduled maintenance to reduce emissions. Consider recycling materials during repairs or upgrades. Implementing sustainable practices, like using renewable energy sources for power, further lessens the compressor’s ecological footprint. By adopting these measures, users can contribute to environmental conservation while maintaining productivity.

The Ingersoll-Rand T30 air compressor is a reliable tool for industrial tasks. By following this manual, users can ensure optimal performance, efficiency, and safety while operating the compressor.

10.1 Summary of Key Points

The Ingersoll-Rand T30 air compressor manual provides essential guidance for safe and efficient operation. Key features include robust construction, high performance, and energy efficiency. Proper installation, regular maintenance, and adherence to safety protocols are crucial for optimal functionality. Users should follow recommended lubrication, filter cleaning, and belt tensioning schedules to extend equipment life. Troubleshooting common issues and understanding technical specifications ensure seamless operation. Compliance with environmental standards and proper waste disposal are emphasized. By following this manual, users can maximize the compressor’s reliability and productivity while minimizing downtime and environmental impact.

10.2 Final Tips for Optimal Performance

Optimize the Ingersoll-Rand T30 air compressor’s performance with regular maintenance and adherence to guidelines. Store it in a clean, dry area to prevent damage. Use genuine parts for efficiency and longevity. Regularly inspect power cords and ensure the power supply meets specifications. Avoid overloading and monitor usage to prevent overheating. Keep the surrounding area clean for better airflow and reduced contamination. Following these tips enhances performance, reliability, and significantly extends the compressor’s lifespan.