The Briggs and Stratton Vanguard Service Manual is a comprehensive guide for engine technicians and users, providing detailed instructions for maintenance, repair, and troubleshooting of Vanguard engines. It covers essential procedures, model-specific information, and safety guidelines to ensure optimal performance and longevity of the engine.

1.1 Overview of the Vanguard Engine Series

The Vanguard engine series, produced by Briggs and Stratton, is a lineup of high-performance, durable engines designed for various applications, including commercial and residential equipment. Known for their reliability and efficiency, these engines are widely used in generators, pressure washers, lawn mowers, and other power equipment. The series includes single-cylinder and V-twin models, offering versatile power solutions. Vanguard engines are equipped with advanced features like electronic fuel injection (EFI) for improved fuel efficiency and performance. This series is favored for its robust design, ease of maintenance, and compatibility with diverse machinery, making it a trusted choice for professionals and homeowners alike.

1.2 Importance of Using the Service Manual

Using the Briggs and Stratton Vanguard Service Manual is essential for ensuring proper maintenance, troubleshooting, and repair of Vanguard engines. It provides detailed instructions, specifications, and safety guidelines to help users avoid costly mistakes and maintain engine performance. The manual includes model-specific information, diagnostic procedures, and repair techniques, making it an indispensable resource for technicians and users. By following the manual, users can ensure compliance with manufacturer recommendations, prevent engine damage, and extend the lifespan of their equipment. It also serves as a reference for understanding technical specifications and torque values, crucial for accurate and efficient servicing.

Safety Guidelines and Precautions

This section outlines crucial safety guidelines for servicing Vanguard engines, including proper handling of fuel, electrical components, and hot engine parts. Always wear protective gear.

2.1 General Safety Tips for Servicing Small Engines

When servicing your Briggs and Stratton Vanguard engine, always disconnect the spark plug wire to prevent accidental starts. Ensure the engine is cool before beginning work. Wear protective gear, including gloves and safety glasses, to prevent injury from sharp edges or debris. Work in a well-ventilated area to avoid inhaling harmful fumes. Never smoked near flammable liquids or fuels. Keep loose clothing and long hair tied back to avoid entanglement with moving parts. Use proper tools and follow approved procedures to maintain safety and prevent damage to the engine.

2.2 Personal Protective Equipment (PPE) Recommendations

- Always wear safety glasses or goggles to protect your eyes from debris and chemicals.

- Use insulated gloves to prevent cuts, abrasions, and electrical shocks.

- Wear a dust mask when handling air filters or cleaning dusty components.

- Protective footwear with non-slip soles is essential for stability while working.

- Consider hearing protection if working in a noisy environment or using power tools.

Proper PPE ensures safety and prevents injuries during engine servicing.

Identifying Your Briggs and Stratton Vanguard Engine

Locate the model number on the engine’s identification label to ensure proper servicing. The model number format is XXXXXX-XXXX, crucial for accurate part identification and repair.

3.1 Locating the Model Number and Serial Number

The model number and serial number are essential for identifying your Vanguard engine and accessing the correct service manual. These numbers are typically found on a label or plate attached to the engine. For most Vanguard models, the label is located near the air filter housing or on the top of the engine block. Ensure the label is clean and legible for accurate identification. The model number format is usually six digits followed by a dash and four more digits (XXXXXX-XXXX). This format is critical for ordering parts and referencing the service manual. Always double-check the numbers to avoid errors in servicing or repairs. Additionally, some models may have the serial number stamped directly onto the engine casing, often near the crankcase. Properly identifying these numbers ensures you can retrieve the correct specifications and procedures for your specific engine, making maintenance and troubleshooting more efficient and effective. By following these steps, you can accurately identify your Vanguard engine and proceed with confidence in servicing it according to the manual’s guidelines. This step is crucial for ensuring that all maintenance and repairs are done correctly, preventing potential damage and extending the engine’s lifespan.

3.2 Understanding the Model Number Format

The Vanguard engine model number is structured to provide detailed information about the engine’s specifications. Typically, the format is a combination of digits and letters, such as XXXXXX-XXXX, where the first six characters identify the engine series, displacement, and configuration. The last four characters denote horsepower, features, or special configurations. Understanding this format helps in identifying the correct parts and procedures for maintenance and repair. Always refer to the model number when ordering parts or consulting the service manual to ensure compatibility and accuracy. This system streamlines the process of servicing your Vanguard engine efficiently.

Maintenance Schedule for Vanguard Engines

Regular maintenance is crucial for extending the life of your Vanguard engine. Follow the schedule for oil changes, air filter cleaning, and spark plug inspections. Perform these tasks every 100 hours of operation to ensure optimal performance and prevent potential issues.

4.1 Routine Maintenance Checks

Routine maintenance checks are essential to ensure the optimal performance of your Vanguard engine. Begin by inspecting the air filter for cleanliness and damage. Replace it if necessary to maintain proper airflow. Next, check the oil level using the dipstick, ensuring it meets the recommended viscosity and fill level. Inspect the spark plug for wear or fouling and replace it every 100 hours of operation. Additionally, examine the fuel line for leaks or blockages and ensure all connections are secure. Finally, verify the condition of the belts and hoses, replacing them if signs of wear are present. Regular inspections help prevent unexpected breakdowns and extend engine life.

4.2 Oil Change and Lubrication Guidelines

Regular oil changes are crucial for maintaining the performance and longevity of your Vanguard engine. Use high-quality oil with a viscosity of 5W-30 or 10W-30, as recommended in the manual. Begin by warming the engine slightly to help drain the oil more efficiently. Locate the oil drain plug at the bottom of the engine and use a socket wrench to remove it. Allow the old oil to drain completely before replacing the plug. Install a new oil filter by hand tightening it in a clockwise direction. Refill the engine with the recommended oil type and check for leaks around the drain plug and filter. Dispose of used oil and filters responsibly. Always refer to the manual for the correct oil capacity and specifications to ensure proper lubrication and engine health.

4.3 Air Filter Cleaning and Replacement

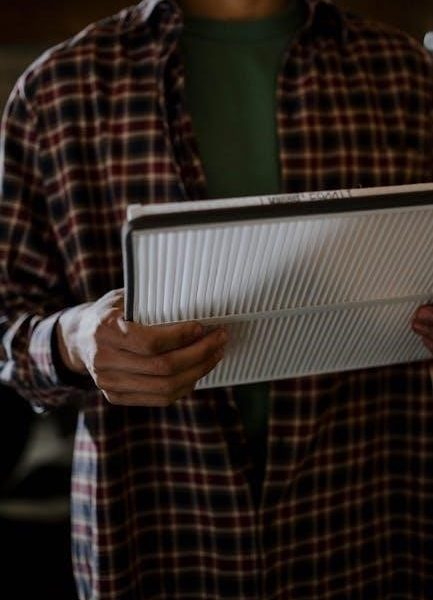

Regular maintenance of the air filter is essential for optimal engine performance. Start by turning off the engine and allowing it to cool. Locate the air filter housing, typically secured with clips or screws, and remove it to access the filter. Inspect the filter for dirt or debris. Foam filters can be cleaned with mild soap and water, then dried thoroughly before reinstallation. Paper filters should not be cleaned and must be replaced if damaged or dirty. Replace the air filter every 100 hours of operation for foam types and every 200 hours for paper types. Ensure the filter is properly seated and aligned with the housing tabs before securing the cover. A clean air filter improves airflow, reducing the risk of engine damage and maintaining efficient combustion. Always refer to the manual for specific replacement intervals and filter types recommended for your Vanguard engine model.

Diagnostic and Troubleshooting Procedures

This section provides step-by-step guidance for identifying and resolving common issues with Vanguard engines. It covers diagnostic tools, trouble code interpretation, and repair strategies to ensure quick resolution.

5.1 Common Issues and Symptoms

Common issues with Vanguard engines include fuel system problems, governor malfunctions, and electrical faults. Symptoms like rough idling, reduced power, or engine stalling often indicate fuel issues or clogged air filters. Governor-related problems may cause engine surging or unstable RPMs. Electrical system faults, such as faulty sensors or wiring, can result in intermittent starting or complete engine shutdown. Identifying these symptoms early helps in preventing major repairs. Always refer to the diagnostic trouble codes (DTCs) for precise troubleshooting and follow the manual’s repair procedures to address these issues effectively.

5.2 Using Diagnostic Tools for Vanguard Engines

Diagnostic tools are essential for identifying and resolving issues in Vanguard engines. The Briggs & Stratton Diagnostic Tool (Part No. 1937004S) is recommended for reading and clearing Diagnostic Trouble Codes (DTCs). Connect the tool to the service port, power the engine, and follow on-screen instructions to retrieve DTCs. This tool provides detailed fault information, enabling precise repairs. Regular updates ensure compatibility with the latest engine models. Always reference the manual for specific diagnostic procedures and ensure the tool is properly calibrated before use for accurate results.

5.3 Reading and Clearing Diagnostic Trouble Codes (DTCs)

Reading and clearing Diagnostic Trouble Codes (DTCs) is crucial for diagnosing issues in Vanguard engines. Use the Briggs & Stratton Diagnostic Tool (Part No. 1937004S) to connect to the engine’s service port. Power the engine and follow the tool’s instructions to retrieve DTCs. Each code corresponds to a specific fault, which can be referenced in the manual. After addressing the issue, clear the codes using the tool. Documenting DTCs aids in tracking recurring problems. Always ensure the tool is updated and properly connected for accurate results. Clearing codes does not resolve the issue; further diagnosis is required.

Repair and Service Procedures

Disassembly and reassembly procedures, carburetor cleaning, and governor adjustments are detailed in this section. It provides step-by-step instructions for common repairs, ensuring proper engine restoration.

6.1 Disassembly and Reassembly of the Engine

Disassembling and reassembling the Vanguard engine requires precision to avoid damage. The manual provides a step-by-step guide, starting with disconnecting the fuel line and spark plug. Important: Mark all connections for proper reinstallation. Remove bolts in a specific order to prevent engine damage. Clean all components thoroughly before reassembly. Reinstall parts in the reverse order of disassembly, ensuring all torque specifications are followed. Refer to the torque chart in the manual for accurate values. Proper alignment and gasket installation are critical for ensuring engine performance and preventing leaks.

6.2 Carburetor Cleaning and Adjustment

Cleaning and adjusting the carburetor is essential for maintaining optimal engine performance. Start by removing the air filter and spraying carburetor cleaner into the intake. Use a small brush to clean stubborn debris in the jets and passages. After cleaning, reassemble the carburetor and adjust the idle mixture and speed screws as specified in the manual. Ensure the engine runs smoothly at various throttle settings. Improper adjustment can lead to poor performance or engine failure. Always refer to the Vanguard service manual for precise torque and adjustment specifications to guarantee reliability and efficiency.

6.3 Governor Adjustment and Calibration

Proper governor adjustment ensures consistent engine speed and performance under varying loads. Start by loosening the governor spring locknut and adjusting the spring to achieve the correct idle speed. Use a screwdriver to fine-tune the governor arm, ensuring smooth throttle transitions from idle to full power. After adjustment, tighten the locknut securely. Calibration may require specialized tools, such as a tachometer, to verify RPM settings. Refer to the Vanguard service manual for specific torque values and adjustment procedures to maintain optimal engine operation and prevent surging or stalling issues.

Technical Specifications and Torque Values

Find detailed engine specifications, bolt torque values, and performance data for Vanguard engines, ensuring accurate servicing and compliance with manufacturer standards for optimal engine operation.

7.1 Engine Specifications and Performance Data

This section provides detailed engine specifications, including horsepower, displacement, cylinder configuration, and fuel system details. It outlines performance metrics such as power output, torque, and operational speeds. Additionally, it covers essential data for proper engine operation, including recommended operating temperatures and pressure levels. These specifications are crucial for troubleshooting, maintenance, and ensuring the engine operates within manufacturer guidelines. By referencing this data, technicians and users can verify engine performance and identify deviations from standard operation, facilitating accurate diagnostics and repairs.

7.2 Bolt and Fastener Torque Specifications

This section outlines the precise torque specifications for bolts and fasteners used in Vanguard engines. Proper torque ensures engine components are securely fastened, maintaining performance and preventing damage. The manual provides detailed values for various bolts, including cylinder head, crankcase, and intake manifold bolts. Following these specifications is critical to avoid over-tightening or under-tightening, which can lead to engine damage or unsafe operation. Referencing these torque values during repairs or maintenance ensures compliance with manufacturer guidelines and maintains engine reliability. Always use a torque wrench and follow the recommended sequence for tightening.

Parts and Accessories for Vanguard Engines

This section helps users identify and order genuine Briggs and Stratton Vanguard engine parts. It provides detailed parts lists, model number references, and ordering instructions for maintenance and repairs.

8.1 Identifying and Ordering Replacement Parts

To identify and order replacement parts for your Briggs and Stratton Vanguard engine, locate the model number on the engine. The model number is typically found on a label or plate and follows a specific format (e.g., XXXXXX-XXXX). Use this number to reference the Illustrated Parts List (IPL) in the service manual or on the Briggs and Stratton website. The IPL provides detailed diagrams and part numbers for every component. Enter the model number on the Briggs and Stratton website to search for genuine parts. Ensure the format is correct, adding a zero if the number is only five digits. This ensures accurate part identification and ordering, preventing delays or incorrect purchases. Always verify compatibility before placing an order. Using genuine parts guarantees performance and longevity. The IPL is a valuable resource for visual identification and ordering accuracy. This step-by-step process ensures you get the right parts efficiently. Proper part identification is crucial for successful repairs and maintenance. Always cross-reference the IPL with your engine’s specifications to avoid mismatches. This method streamlines the process, saving time and reducing errors. Ordering genuine parts ensures reliability and maintains your engine’s warranty. The IPL is updated regularly, so always refer to the latest version for accuracy. This approach ensures your Vanguard engine operates at peak performance. Regularly updating your parts list helps maintain engine health. By following these steps, you can identify and order the correct parts with confidence. Proper part identification is essential for maintaining your engine’s performance and longevity. The IPL is your key to quick and accurate part replacement. Using genuine parts ensures your engine runs smoothly and reliably; Always double-check your model number and part compatibility before ordering. This guarantees a seamless repair process. The IPL is designed to simplify part identification, making it easier to keep your engine in top condition. Ordering genuine parts is the best way to maintain your Vanguard engine’s performance and durability. The IPL and online resources provide everything needed for accurate part identification and ordering. This ensures your engine receives the correct components for optimal operation. By following these guidelines, you can efficiently identify and order the right parts for your Vanguard engine. Proper part identification and ordering are critical for successful maintenance and repairs. The IPL and Briggs and Stratton website are essential tools for this process. Always use genuine parts to maintain your engine’s performance and warranty. This step-by-step approach ensures accuracy and efficiency in part replacement. The IPL is a comprehensive resource for visual identification and ordering. By referencing the IPL and entering the correct model number, you can quickly find and order the parts you need. This method ensures your Vanguard engine is serviced with genuine, high-quality components. Proper part identification and ordering are vital for maintaining your engine’s health. The IPL and online tools make this process straightforward. Always prioritize genuine parts for reliability and performance. The IPL is your guide to accurate part identification and ordering. This ensures your Vanguard engine runs smoothly and efficiently. By following these steps, you can identify and order replacement parts with confidence. Proper part identification is crucial for successful repairs and maintenance. The IPL is a valuable resource for visual identification and ordering. Using genuine parts ensures your engine operates at its best. Always double-check your model number and part compatibility before ordering. This guarantees a seamless repair process. The IPL is designed to simplify part identification, making it easier to keep your engine in top condition. Ordering genuine parts is the best way to maintain your Vanguard engine’s performance and durability. The IPL and online resources provide everything needed for accurate part identification and ordering. This ensures your engine receives the correct components for optimal operation. By following these guidelines, you can efficiently identify and order the right parts for your Vanguard engine. Proper part identification and ordering are critical for successful maintenance and repairs. The IPL and Briggs and Stratton website are essential tools for this process. Always use genuine parts to maintain your engine’s performance and warranty. This step-by-step approach ensures accuracy and efficiency in part replacement. The IPL is a comprehensive resource for visual identification and ordering. By referencing the IPL and entering the correct model number, you can quickly find and order the parts you need. This method ensures your Vanguard engine is serviced with genuine, high-quality components. Proper part identification and ordering are vital for maintaining your engine’s health. The IPL and online tools make this process straightforward. Always prioritize genuine parts for reliability and performance. The IPL is your guide to accurate part identification and ordering. This ensures your Vanguard engine runs smoothly and efficiently. By following these steps, you can identify and order replacement parts with confidence. Proper part identification is crucial for successful repairs and maintenance. The IPL is a valuable resource for visual identification and ordering. Using genuine parts ensures your engine operates at its best. Always double-check your model number and part compatibility before ordering. This guarantees a seamless repair process. The IPL is designed to simplify part identification, making it easier to keep your engine in top condition. Ordering genuine parts is the best way to maintain your Vanguard engine’s performance and durability. The IPL and online resources provide everything needed for accurate part identification and ordering. This ensures your engine receives the correct components for optimal operation; By following these guidelines, you can efficiently identify and order the right parts for your Vanguard engine. Proper part identification and ordering are critical for successful maintenance and repairs. The IPL and Briggs and Stratton website are essential tools for this process. Always use genuine parts to maintain your engine’s performance and warranty. This step-by-step approach ensures accuracy and efficiency in part replacement. The IPL is a comprehensive resource for visual identification and ordering. By referencing the IPL and entering the correct model number, you can quickly find and order the parts you need. This method ensures your Vanguard engine is serviced with genuine, high-quality components. Proper part identification and ordering are vital for maintaining your engine’s health. The IPL and online tools make this process straightforward. Always prioritize genuine parts for reliability and performance. The IPL is your guide to accurate part identification and ordering. This ensures your Vanguard engine runs smoothly and efficiently. By following these steps, you can identify and order replacement parts with confidence. Proper part identification is crucial for successful repairs and maintenance. The IPL is a valuable resource for visual identification and ordering. Using genuine parts ensures your engine operates at its best. Always double-check your model number and part compatibility before ordering. This guarantees a seamless repair process. The IPL is designed to simplify part identification, making it easier to keep your engine in top condition. Ordering genuine parts is the best way to maintain your Vanguard engine’s performance and durability. The IPL and online resources provide everything needed for accurate part identification and ordering. This ensures your engine receives the correct components for optimal operation. By following these guidelines, you can efficiently identify and order the right parts for your Vanguard engine. Proper part identification and ordering are critical for successful maintenance and repairs. The IPL and Briggs and Stratton website are essential tools for this process. Always use genuine parts to maintain your engine’s performance and warranty. This step-by-step approach ensures accuracy and efficiency in part replacement. The IPL is a comprehensive resource for visual identification and ordering. By referencing the IPL and entering the correct model number, you can quickly find and order the parts you need. This method ensures your Vanguard engine is serviced with genuine, high-quality components. Proper part identification and ordering are vital for maintaining your engine’s health. The IPL and online tools make this process straightforward. Always prioritize genuine parts for reliability and performance. The IPL is your guide to accurate part identification and ordering. This ensures your Vanguard engine runs smoothly and efficiently. By following these steps, you can identify and order replacement parts with confidence. Proper part

8.2 Illustrated Parts List (IPL) for Vanguard Engines

The Illustrated Parts List (IPL) for Briggs and Stratton Vanguard engines is a detailed catalog that visually identifies every component of the engine. Organized by sections, it provides part numbers, descriptions, and diagrams to help users locate and order genuine parts. The IPL is accessible via the Briggs and Stratton website or through the service manual. It ensures accurate identification of components, reducing errors in part ordering. Regularly updated, the IPL reflects the latest engineering specifications. Users can search by model number to find specific parts, making it an essential tool for maintenance, repairs, and ensuring compatibility. The IPL is a visual guide that simplifies parts identification, guaranteeing the correct components for your Vanguard engine.

Fuel and Oil Recommendations

Briggs and Stratton Vanguard engines require specific fuel and oil to ensure optimal performance. Use unleaded gasoline with a minimum of 87 octane for fuel. For oil, synthetic or high-quality detergent oil with the recommended viscosity is essential for engine longevity and efficiency. Always refer to the service manual for exact specifications tailored to your engine model and operating conditions to maintain warranty and performance standards.

9.1 Approved Fuel Types and Octane Ratings

Briggs and Stratton Vanguard engines require unleaded gasoline with a minimum octane rating of 87. Ethanol blends up to E10 are acceptable, but higher ethanol content, such as E15, should be avoided to prevent engine damage. Using the correct fuel type ensures optimal engine performance, efficiency, and longevity. Always refer to the service manual for specific recommendations tailored to your engine model. Proper fuel selection helps maintain engine health and prevents issues like corrosion or combustion problems. Adhering to these guidelines is essential for warranty compliance and overall engine reliability.

9.2 Recommended Oil Viscosity and Brands

Briggs and Stratton recommends using high-quality oil with a viscosity of SAE 10W-30 or 10W-40 for Vanguard engines. These viscosities ensure optimal performance across various temperatures. Approved oil brands include Briggs & Stratton, Mobil, and Castrol. Synthetic oil is recommended for extreme conditions, such as high heat or cold. Always refer to the service manual for model-specific recommendations. Using the correct oil viscosity and brand ensures proper engine lubrication, reduces wear, and extends service life. Proper oil selection is crucial for maintaining engine health and performance.

Electrical and Wiring Diagrams

The manual provides detailed electrical and wiring diagrams for Vanguard engines, aiding in troubleshooting and repairs. These diagrams outline the wiring harness layout and connections, ensuring accurate diagnostics and service.

10.1 Understanding the Wiring Harness

The wiring harness in Briggs and Stratton Vanguard engines is a critical component that connects electrical systems, ensuring proper communication and power distribution. It consists of wires, connectors, and terminals that link components like sensors, ignition systems, and diagnostic tools. The harness is designed to withstand harsh environments and provide reliable performance. Proper understanding of its layout and connections is essential for troubleshooting and repairs. The service manual provides detailed diagrams and descriptions to help technicians identify and service the wiring harness effectively, ensuring optimal engine functionality and reducing the risk of electrical failures.

10.2 Troubleshooting Electrical System Issues

Troubleshooting electrical system issues in Briggs and Stratton Vanguard engines involves identifying symptoms like faulty starts, flickering lights, or diagnostic trouble codes (DTCs). Use the Briggs and Stratton Diagnostic Tool to read DTCs, which provide insights into specific electrical faults. Check connections, fuses, and wiring for damage or corrosion. Test components such as sensors, spark plugs, and ignition coils for proper function. Refer to the service manual for detailed diagnostic procedures and wiring diagrams. Addressing issues promptly prevents further damage and ensures reliable engine performance. Always follow safety guidelines when working with electrical systems to avoid accidents or injuries.

Environmental and Storage Guidelines

Proper storage ensures engine longevity. Drain fuel, clean thoroughly, and use vapor-resistant containers. Check for spills and environmental compliance to prevent contamination and eco-friendly maintenance.

11.1 Proper Storage Procedures for Vanguard Engines

- Drain fuel from the tank and lines to prevent corrosion and contamination.

- Clean the engine thoroughly, removing dirt and debris to avoid damage during storage.

- Apply a rust-inhibiting oil to exposed metal parts to protect against moisture.

- Store the engine in a dry, well-ventilated area, away from direct sunlight and extreme temperatures.

- Use a breathable cover to protect from dust and pests while allowing airflow.

- Avoid stacking heavy objects on the engine to prevent physical damage.

- Check for any signs of wear or damage before storing for extended periods.

- Consult the manual for specific storage recommendations based on the engine model.

11.2 Environmental Considerations for Maintenance

Proper environmental practices are crucial when maintaining Vanguard engines. Dispose of used oil, fuel, and filters responsibly through approved recycling centers. Avoid draining fluids into the ground or waterways, as this can harm ecosystems. Use eco-friendly cleaning agents for engine parts and ensure all rags and materials are disposed of correctly. Always follow local regulations for hazardous waste disposal. Additionally, use Briggs & Stratton-approved parts to minimize environmental impact. Regular maintenance helps reduce emissions and ensures efficient engine operation, contributing to a cleaner environment.

Appendices and Resources

The appendices section provides a glossary of technical terms, contact information for authorized dealers, and online resources for further troubleshooting and repair guidance.

12.1 Glossary of Technical Terms

This section provides definitions for key technical terms used throughout the manual; Terms like DTC (Diagnostic Trouble Code), EFI (Electronic Fuel Injection), and IPL (Illustrated Parts List) are explained to ensure clarity. The glossary helps users understand specialized vocabulary related to engine diagnostics, maintenance, and repair procedures. Familiarity with these terms aids in effectively using the manual for servicing Vanguard engines. Definitions are concise and specific to Briggs and Stratton terminology, making the manual accessible to both professionals and DIY enthusiasts; This reference tool enhances understanding and application of the service procedures outlined in the manual.

12.3 Online Resources for Further Assistance

12.2 Contact Information for Authorized Dealers

For genuine parts, service, or technical support, contact Briggs and Stratton authorized dealers. Visit the official website at www.briggsandstratton.com to locate a dealer near you. Use the “Find a Dealer” tool by entering your location or model number. Dealers provide authentic parts, repair services, and expert advice. Contact their customer support directly via phone or email for inquiries or assistance. Ensure to reach out to authorized dealers for reliable and warranty-compliant services. This resource helps users maintain their Vanguard engines with trusted support and genuine components.